The logic of individual production processes requires high problem-solving expertise by a professional supplier. Optimum process operations, saving of production costs and flexibility in order processing are that kind of added value that is accompanied by an automation solution.

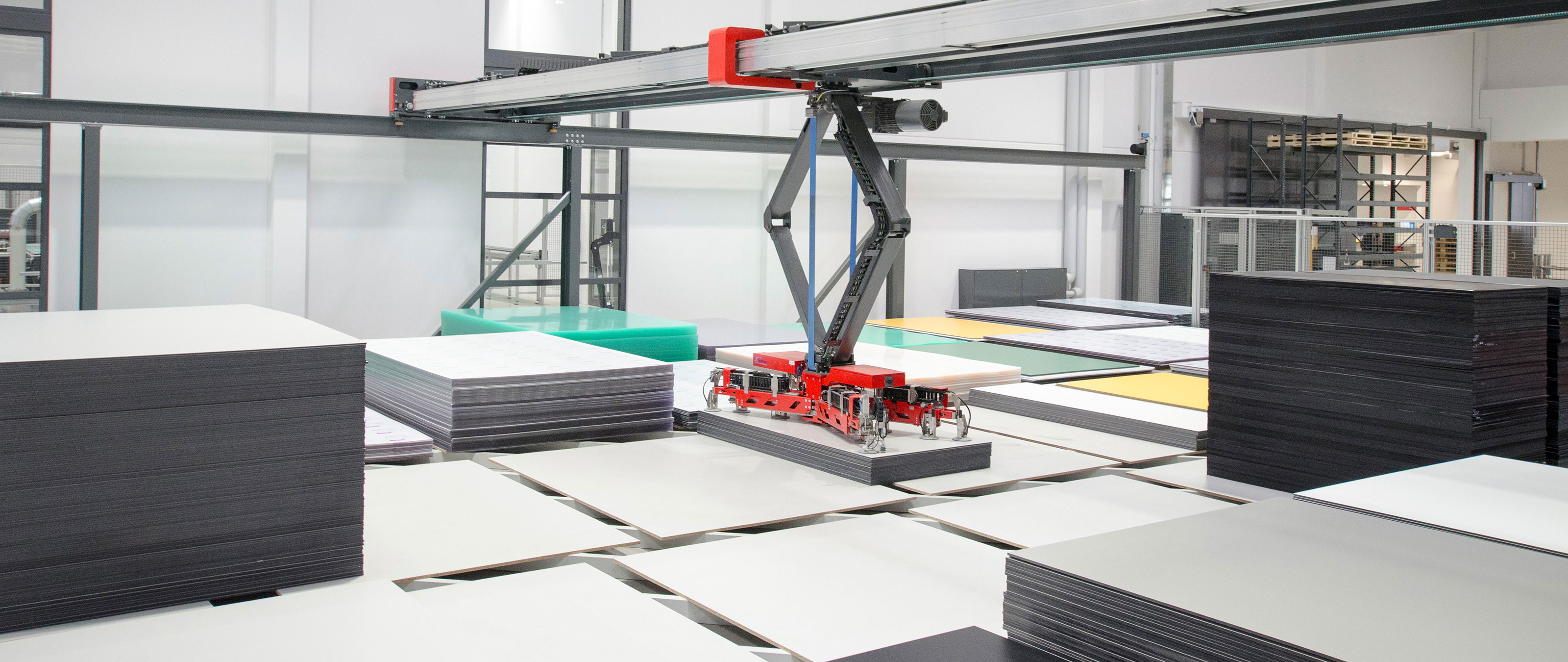

Automatic handling of plastic sheets

item develops and sells solutions for the production of machines, operating facilities, and systems since 1976. The product portfolio comprises more than 3,000 high-quality components for the design of machine frames, workplaces, automation solutions, and lean production applications. item is a global successful provider of system production kits for industrial application.

item relies on the processing of plastic sheets for a part of its products. Different in color, thickness, and size according to the product. item opts for a HOMAG solution for the handling, processing and necessary process flexibility.

Plastic sheets for the production are organized in a storage system in an area of more than 500 m² and variably provided according to customer’s requirements or automatically according to production list to the two linked panel saws at the Solingen plant. The storage systems with the control software woodStore provide the required data flow - a guarantee for full transparency and cost control.

In the past, item stored the plastic sheets in a shelf warehouse. The sequence of processing and the required panel cuttings were determined by the sheets pre-placed in the stack. This was anything but ideal, since it had to be laboriously restacked and the material was transported to the panel saws by means of a lift truck.

Increase of added value by means of automation

Production processes have been optimized for different kind of panels due to the HOMAG solution. There is no operator at the system except for the storing of new panel packs by a fork lift truck. If something has to be controlled at the storage, this is done by the operator of the saw. The process planning manages the master data and the data for optimization from the office workstation. So, the process planning has the necessary transparency and can see which material is available and in which quantity. Whereas the cutter can focus entirely on the processing of panels and the maintenance of the equipment. The storage system carries out the tasks, such as restacking, material provision, or even the pre-collating of panel packs for the daily performance automatically. This advantage is especially obvious, if production is designed for a kind of production where many different panels have to be stored, transported, and cut. At item, different surfaces and panel weights up to 350 kg are no handling problem for the storage system. The dual scissor handles lightweights with the same ease and separates them perfectly. The cutting quality should also be improved by the use of the new system.

2 panel saws process the plastic sheets according to their characteristics. item does not know downtimes and set-up times since then. Competitive advantage is already created at the beginning of the process chain - in the logistics. Here, the intelligent multi-talents among the storage systems and the variants of operating machines from HOMAG are the best solution.

Video

Whach the video and experience how item automates its panel handling with the storage system STORETEQ S-500.

More about item Industrietechnik

item develops and sells solutions for the production of machines, operating facilities, and systems since 1976. The product portfolio comprises more than 3,000 high-quality components for the design of machine frames, workplaces, automation solutions, and lean production applications. item is a global successful provider of system production kits for industrial application.

www.item24.de