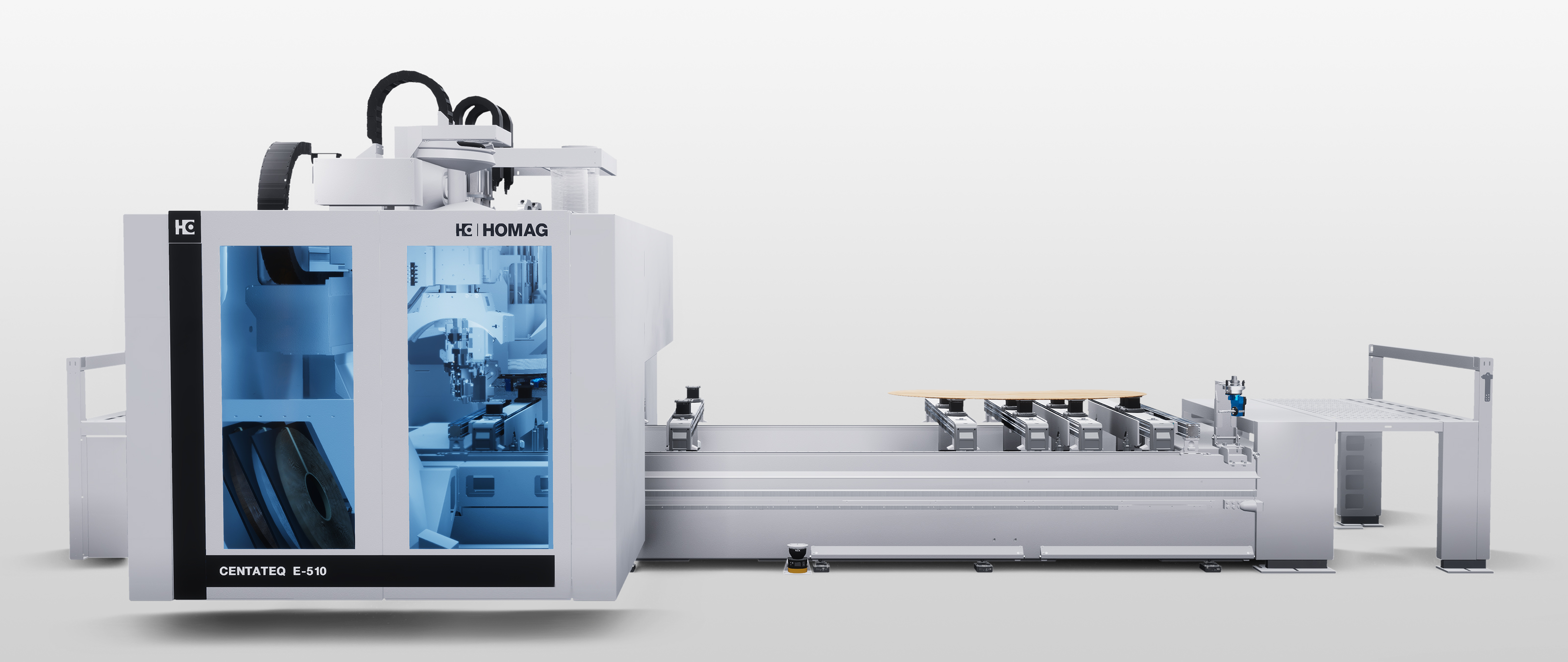

CNC Machining Centers CENTATEQ P-510|610 + E-510

CNC Machining Centers CENTATEQ P-510|610 + E-510

Your choice in CNC machining for demanding production requirements

Stairs, furniture, windows, doors, interior fittings – the machines in our CENTATEQ P-510|610 + E-510 series provide you with the optimum equipment for all of your work. Each of these CNC machines is a complete system, ensuring maximum performance and efficiency to fulfil your customers' individual requirements. Experience the versatility and performance of our systems for your-self.

Benefits

Images

Features

-

Staircase construction, furniture manufacturing, window processing, interior fittings, door production — the right choice for any production task

-

Offering optimum processing quality thanks to vibration damping, and extremely robust thanks to the basic machine construction from solid SORB TECH composite material

-

Scalable performance — configure your new machine with up to three processing units

-

Damage to the trimming spindles is avoided thanks to the regulated main spindle with electronic speed monitoring including vibration sensors

-

Drill change without tools thanks to high-speed drill technology with patented quick-change system

-

Console table, automatic setup A-table or aluminum grid table — choose the right processing table for you

-

Energy-saving features inside, such as intelligent flap control, which reduces suction costs by up to 20%

Technical Data

| Workpiece length X [mm] | /33 | /40 | /60 | /74 |

|---|---|---|---|---|

| Individual processing (all units) | 3,300 | 4,000 | 6,000 | 7,400 |

| Pendelbearbeitung* (all units) | 1,025 | 1,375 | 2,375 | 3,075 |

| Workpiece width Y [mm] | /xx/12 | /xx/15 | /xx/19 | /xx/29 |

|---|---|---|---|---|

| All units in main spindle (front stop) | 1,100 | 1,450 | 1,800 | 2,800 |

| With tool diameter 25 mm (rear stop) | 1,550 | 1,900 | 2,250 | 3,250 |

| Gluing (rear stop) | 1,550 | 1,900 | 2,250 | -- |

| Workpiece thickness Z [mm] | 510 | 610 |

|---|---|---|

| With tool length 230 mm | 300 | 500 |

Some workpiece parameters may depend on the tools used. Please see the relevant brochure for further technical data.

*Dimension with central division. Pendulum field size adjusted dynamically to component size.

(Previous product name: BMG 510|610 processing centers)

Here's how your colleagues produce

Videos

HOMAG CENTATEQ P-510 | Window production with 3-stage clamps

The CENTATEQ P-510 is the right choice for demanding production requirements such as stairs, furniture, windows, doors and interior fittings.

Brochures