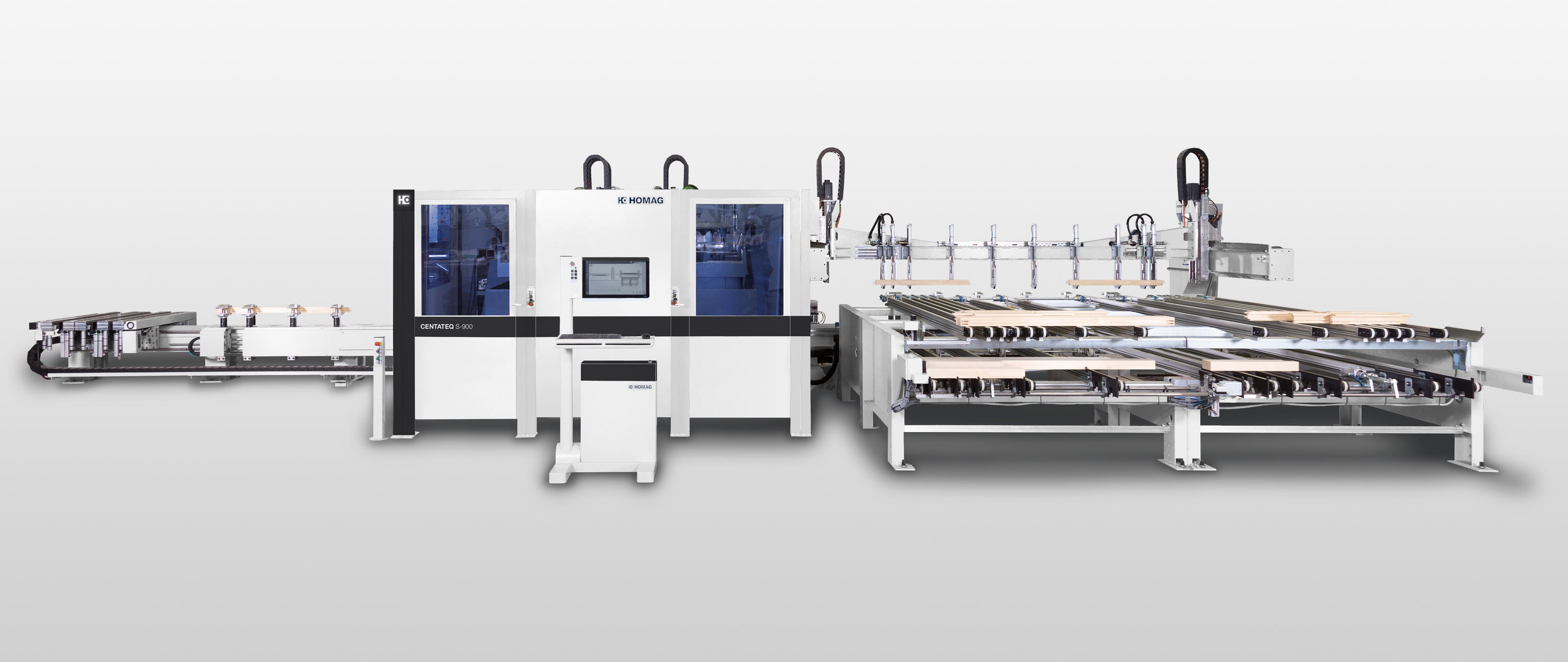

CNC Machining Centers CENTATEQ S-800|900

CNC Machining Centers CENTATEQ S-800|900

A firm "grip" on window production

This series offers automated window production solutions – from entry-level machines to individual plant concepts for industrial multi-shift operation. With automated feed and removal, these solutions work independently. The additional console table also enables you to process curved and surface parts. The result: One machine for all components.

Benefits

Images

Features

-

Optimum processing quality with the basic machine comprising a heavy-duty gantry bridge plus compact, rigid guide track for the clamping tables

-

Dual-level infeed and outfeed for centralized workpiece handling

-

Precise clamping of components in all directions thanks to gripper system that pivots on both sides

-

High-performance processing spindles with liquid cooling, a variable speed range, vector control and a spindle sensor that detects imbalances and vibrations, thus protecting the spindle

-

Minimal clamp-to-clamp time thanks to compact tool magazines in different sizes with inte-grated pre-changing system

Technical Data

| Workpiece parameters | |

|---|---|

| Workpiece width [mm] | 20 - 300 |

| Workpiece height [mm] | 25 - 150 |

| Workpiece length [mm] | up to 4,200 for automatic operation up to 6,000 with reclamping |

(Previous product name: BMB 800|900 processing centers)

Here's how your colleagues produce

Videos

CENTATEQ S-800|900 processing centers

Window production: The 3rd generation of the powerProfiler - dynamic, fast, precise and flexible

Brochures