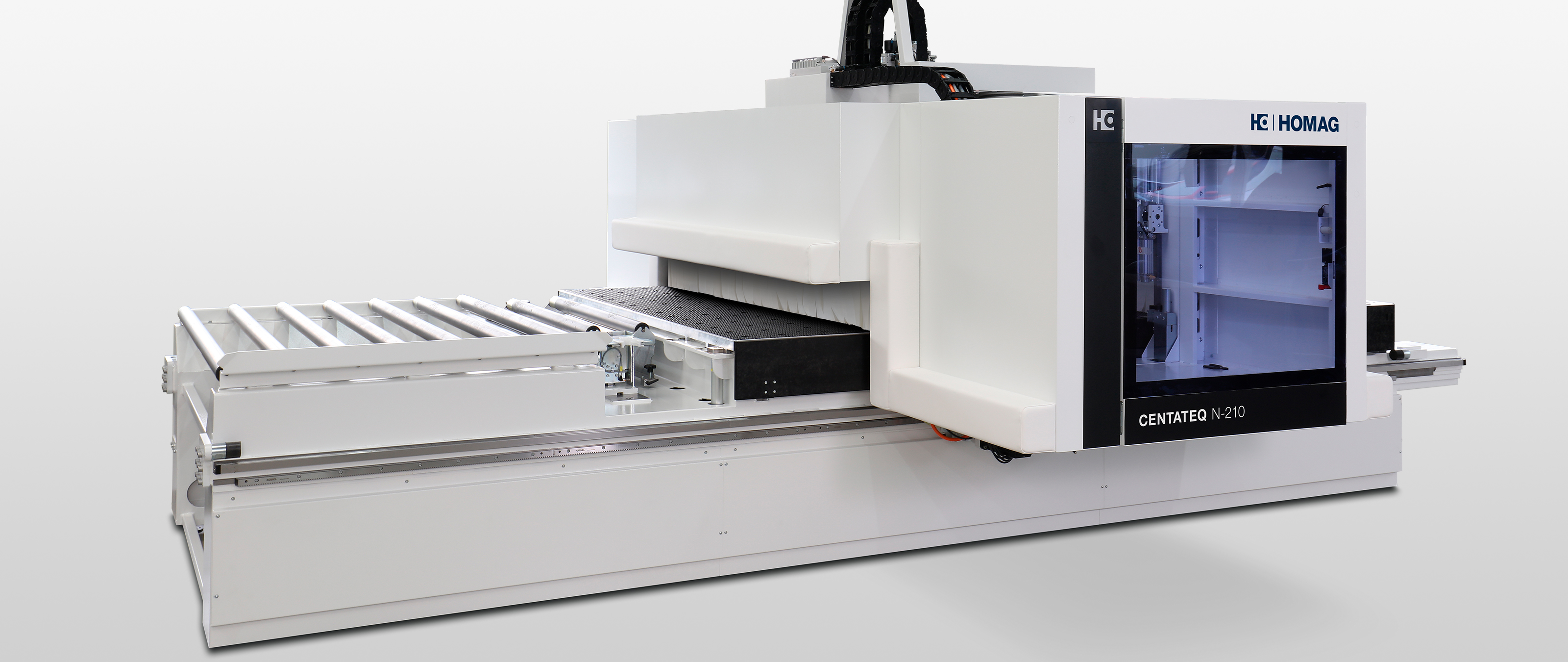

CNC Machining Centers CENTATEQ N-210

CNC Machining Centers CENTATEQ N-210

The new Nesting concepts: Individual automation for furniture production

Our nesting machines allow for machining and dividing of panel-shaped materials with waste reduction as a focus. The traditional nested based field is in the creation of carcass furniture, or the dividing and finishing of furniture fronts. Automation concepts, which are easy to connect via Plug & Play, offer the possibility of subsequent additions to the machine. Differently equipped drilling gears and tool changers offer a high degree of diversity. With a focus on sustainability, changeover times have been reduced, and chip extraction and vacuum suction have also been optimized.

Benefits

Images

Features

-

Processing height in Z-direction to 160mm material thickness possible without any problems.

-

Integration of the infeed device into the machine housing to protect components from dirt and dust and facilitate material handling.

-

Energy efficient machining. Sustainable design for vacuum generation, tool change and suction during nest splitting.

-

Dynamic shuttle operation using separate vacuum supply and ventilation of the table halves for efficient and seamless changeover between left and right table halves.

-

Newly designed MATRIX table with defined grid dimensions. Cross-segment positioning of suction cups possible without restriction.

-

Optimized suction volume thanks to CFD flow simulation. Redesigned central suction nozzle and change in the arrangement of the integrated blowing nozzles.

Software

Brochures