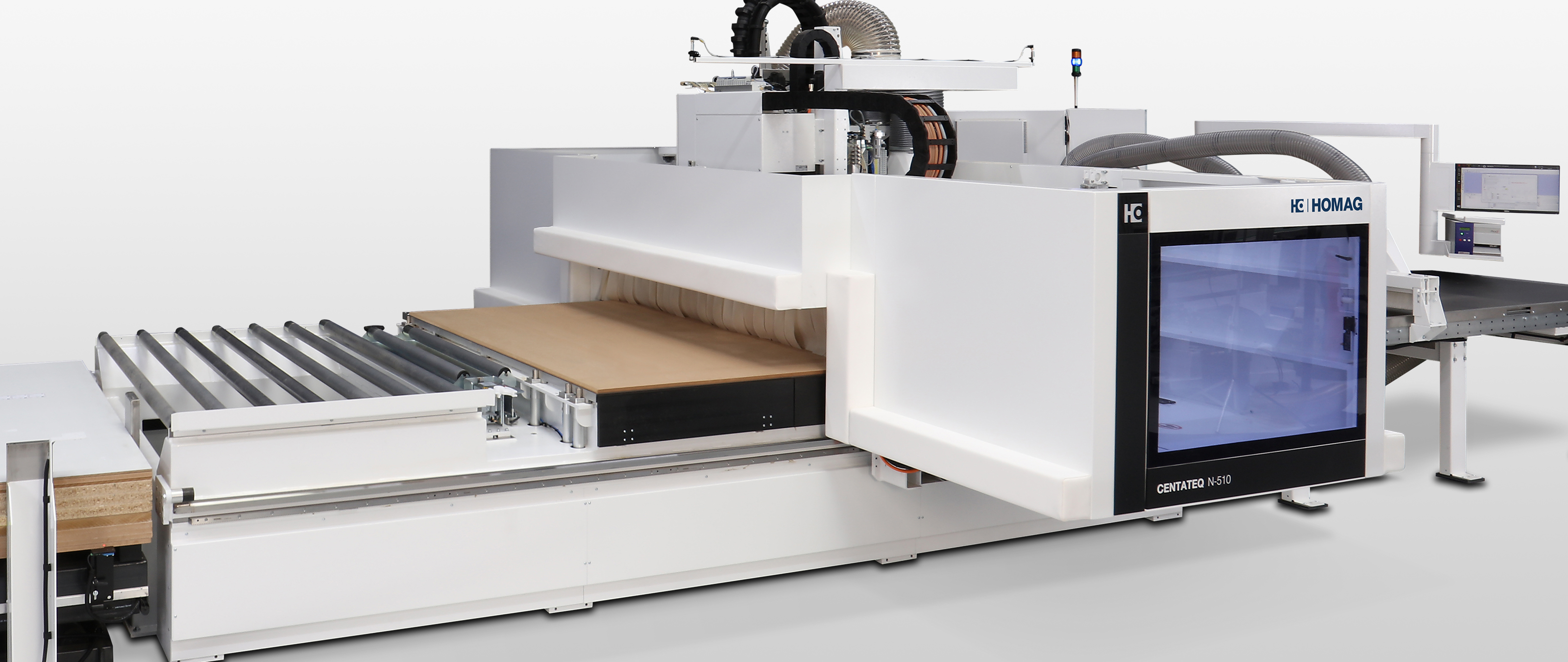

CNC Machining Centers CENTATEQ N-510

CNC Machining Centers CENTATEQ N-510

The new Nesting concepts: Individual automation with 5-axis processing

Our nesting machines allow for machining and dividing of panel-shaped materials with waste reduction as a focus. In addition to the classical nested based fields of application for the production of carcass furniture, or the dividing and finishing of furniture fronts, our solution allows for stair stringers and door leaves to be processed without any problems. Automation concepts, which are easy to connect via Plug & Play, offer the possibility of subsequent additions to the machine. Differently equipped drilling gears and tool changers offer a high degree of diversity. With a focus on sustainability, changeover times have been reduced, and chip extraction and vacuum suction have also been optimized.

Benefits

Images

Features

-

5-axis processing with DRIVE5CS 5-axis-head offers that extra bit of processing versatility. Thanks to new overall height in Z-direction to 260mm material thickness possible without any problems.

-

Integration of the infeed device into the machine housing to protect components from dirt and dust and facilitate material handling.

-

Energy efficient machining. Sustainable design for vacuum generation, tool change and suction during nest splitting.

-

Dynamic shuttle operation using separate vacuum supply and ventilation of the table halves for efficient and seamless changeover between left and right table halves.

-

Newly designed MATRIX table with defined grid dimensions. Cross-segment positioning of suction cups possible without restriction.

-

Optimized suction volume thanks to CFD flow simulation. Redesigned central suction nozzle and change in the arrangement of the integrated blowing nozzles.

Software

Videos

HOMAG CENTATEQ N-510 | The new nesting generation

Our nesting machines allow for machining and dividing of panel-shaped materials with waste reduction as a focus.

Brochures