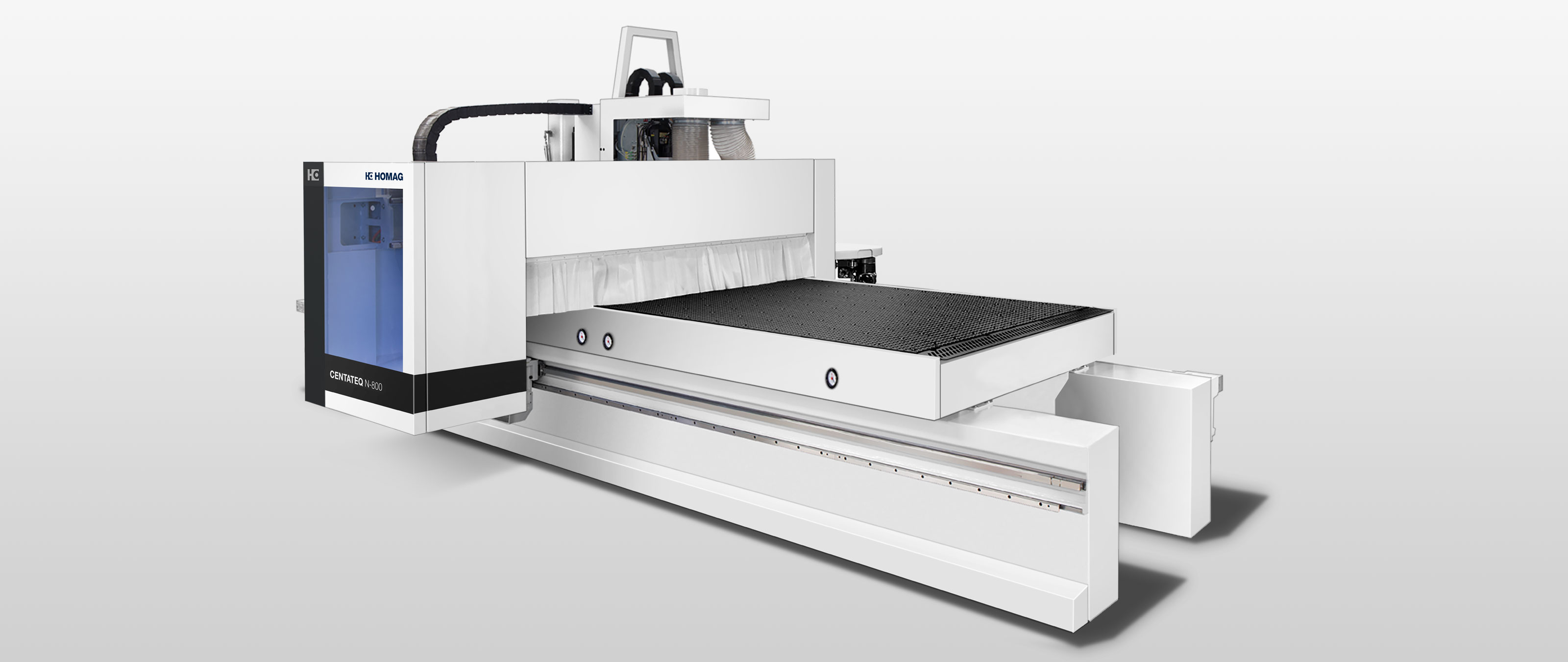

CNC Machining Centers CENTATEQ N-800

CNC Machining Centers CENTATEQ N-800

The power pack among our nesting solutions

Our nesting machines enable cutting-optimized processing and dividing of plate-shaped materials. The typical applications of nesting are creation of carcass furniture, dividing and refining of furniture fronts, construction of frame furniture and creation of components for the caravan constructions and for the structural facings sector. Various possibilities for the automation of the material handling ensure a high time saving and an even more effective work. Cutting-optimized processing and splitting of plate-shaped materials is child's play with the CENTATEQ N-800.

Benefits

Images

Features

-

The whole working field is reachable with all processing tools

-

C-axis with Flex 5Plus unit

-

10 kW air-cooled HSK routing spindle in standard (optional: 13.2 kW air-cooled or 11 kW/16 kW liquid-cooled)

-

Efficient use of energy through high vacuum performances and simultaneously minor power consumption

-

Tool changing system with up to 42 places

-

As individual as your applications

Technical Data

| CENTATEQ N-800 | Table | Table | Table | Table | Table | Table | Table | Table | Table |

|---|---|---|---|---|---|---|---|---|---|

| Table width [mm | feet] |

|

|

|

|

|

|

|

|

|

| Table length [mm | feet] |

|

|

|

|

|

|

|

|

|

| Z stroke | drilling [mm] | 240 | ||||||||

| Z stroke | routing [mm] | 375 | ||||||||

| Z stroke | workpiece [mm] | 125 | ||||||||

| Vacuum capacity [m³/h] | 580–870 depending on table size | ||||||||

Other table sizes available on request.

Technical information is subject to change.

(Previous product name: CNC-Portalbearbeitungszentrum BHP 210)