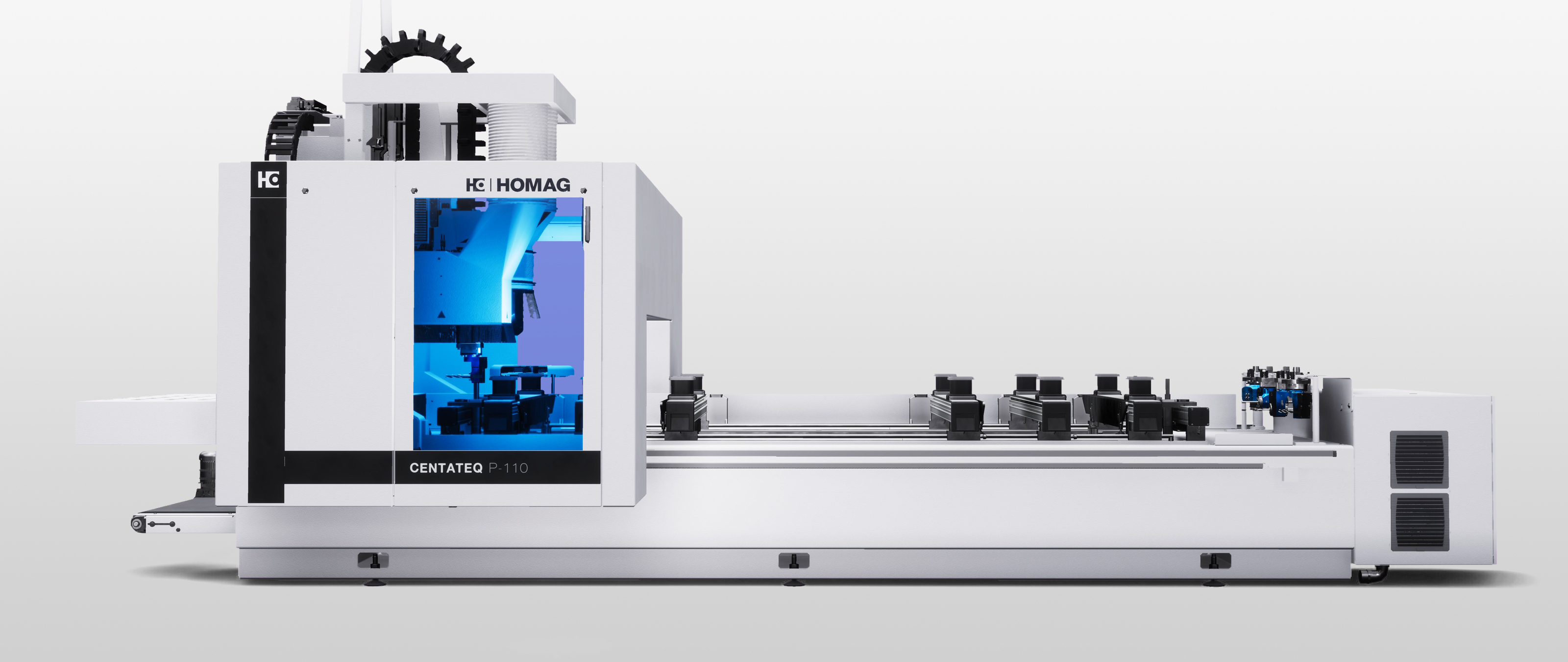

CNC Machining Centers CENTATEQ P-110

CNC Machining Centers CENTATEQ P-110

Freestyle technology with 3-, 4- and 5-axis solutions

This series offers high levels of performance and versatility to small and medium-sized car-pentry and joinery companies. The new machine concept is based on compact technology, a reduced installation area and operation directly at the machine. The CENTATEQ P-110 series includes 3-, 4- and 5-axis solutions for the processing of kitchen, office and solid wood furniture, as well as for the construction of stairs, windows and doors.

Benefits

Images

Features

-

Unit technology...

3-, 4- and 5-axis versions available. An all-rounder for users with demanding requirements.

-

360° access for more space...

The integrated switch cabinet, bumper technology and mobile operator terminal reduce the installation area by up to 15% and ensure easy access from all sides.

-

A heavyweight...

Precise processing is ensured by the heavy steel welded machine frame and stable sliding gantry design.

-

Convenience package (option)

Operating functions can be activated at the touch of a button directly on the machine. An integrated proximity scanner for intelligent pausing is included.

-

Always in view...

Optimal view into the machine with a large viewing window to ensure maximum protection for the operator.

Start now!

Technical Data

| 1 Z-axis | 2 Z-axes | |

|---|---|---|

| Workpiece length X [mm] – Individual processing (tool length 195 mm with all aggregates) | Length M: 3,100 | |

| Workpiece length X [mm] – Alternating processing (tool length 195 mm with all aggregates) | Length M: 1,025 | |

| Workpiece length X [mm] – Individual processing (with tool diameter 25 mm) | Length M: 3,300 | |

| Workpiece width Y [mm] (with tool diameter 25 mm, rear stop) | 1,550 | 1,415 |

| Workpiece width Y [mm] (tool length 200 mm with all aggregates, rear stop) | 1,440 | 1,210 |

| Workpiece thickness Z [mm] – from console | 260 | 260 |

Some workpiece parameters may depend on the tools used. Please see the relevant brochure for further technical data.

Technical information is subject to change.

(Previous product name: Venture 113/114/115 processing centers | BMG 110 series)

Here's how your colleagues produce

Brochures