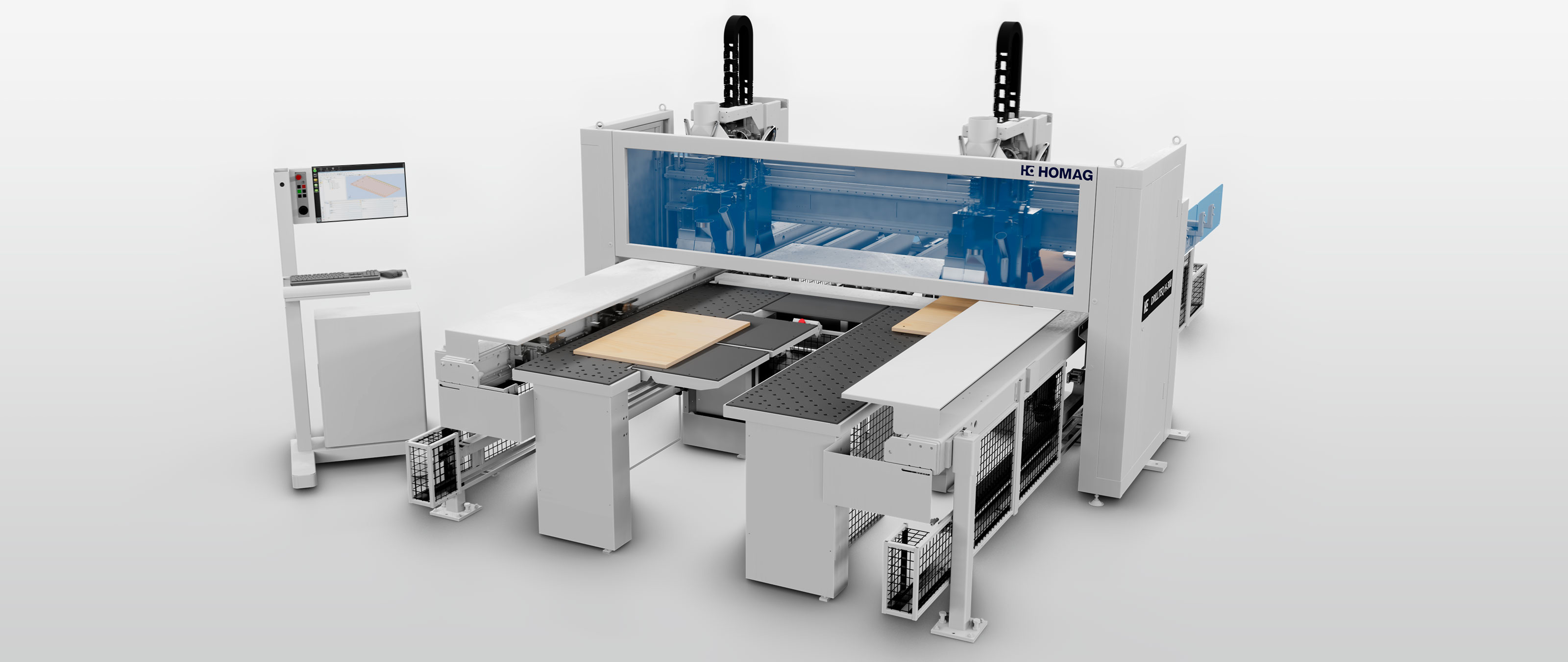

CNC Drilling and Routing Machining Centers DRILLTEQ H-308 | H-310

CNC Drilling and Routing Machining Centers DRILLTEQ H-308 | H-310

Two in one. 6-sided processing.

By feeding two work fields at the same time, the DRILLTEQ H-308 offers virtually two machines in one. While production is running on one work field, the workpiece can already be prepared for seamless further processing on the second. This guarantees high availability and highly flexible production. The machine running time can be extended up to almost 75%. Work interruptions such as breaks or downtimes are reduced to a minimum. Whether flexibility for high variant diversity through batch size 1 production or efficiency through series production – the DRILLTEQ H-308 offers the right solution for you.

Benefits

Images

Technical Data

| Footprint without Switch Cabinet | ||

| L | mm | 5.910 |

| W | mm | 3.900 |

| H | mm | 2.530 |

| Workpiece dimension | ||

| Length | mm | 250 – 2.500 (3.050) |

| Width (single part) | mm | 60 – 1.250 |

| Width (double parts) | mm | 2 x 620 |

| Height | mm | 8 – 40 |

| Drilling Head TOP 1 & 2 | ||

| Vertical spindles | No. | 2 x 13 |

| Vertical spindle clamping | patented | Yes |

| Horizontal spindles in X+/X- | No. | 2 x (3X+/3X-) |

| Horizontal spindles in Y+/Y- | No. | 2 x (3Y+/3Y-) |

| Frequency controlled | RPM | 1.250 – 7.500 |

| Drilling Head Bottom 1 | ||

| Vertical spindles | No. | 14 |

| Vertical spindle clamping | patented | Yes |

| Frequency controlled | RPM | 1.250 – 7.500 |

Brochures