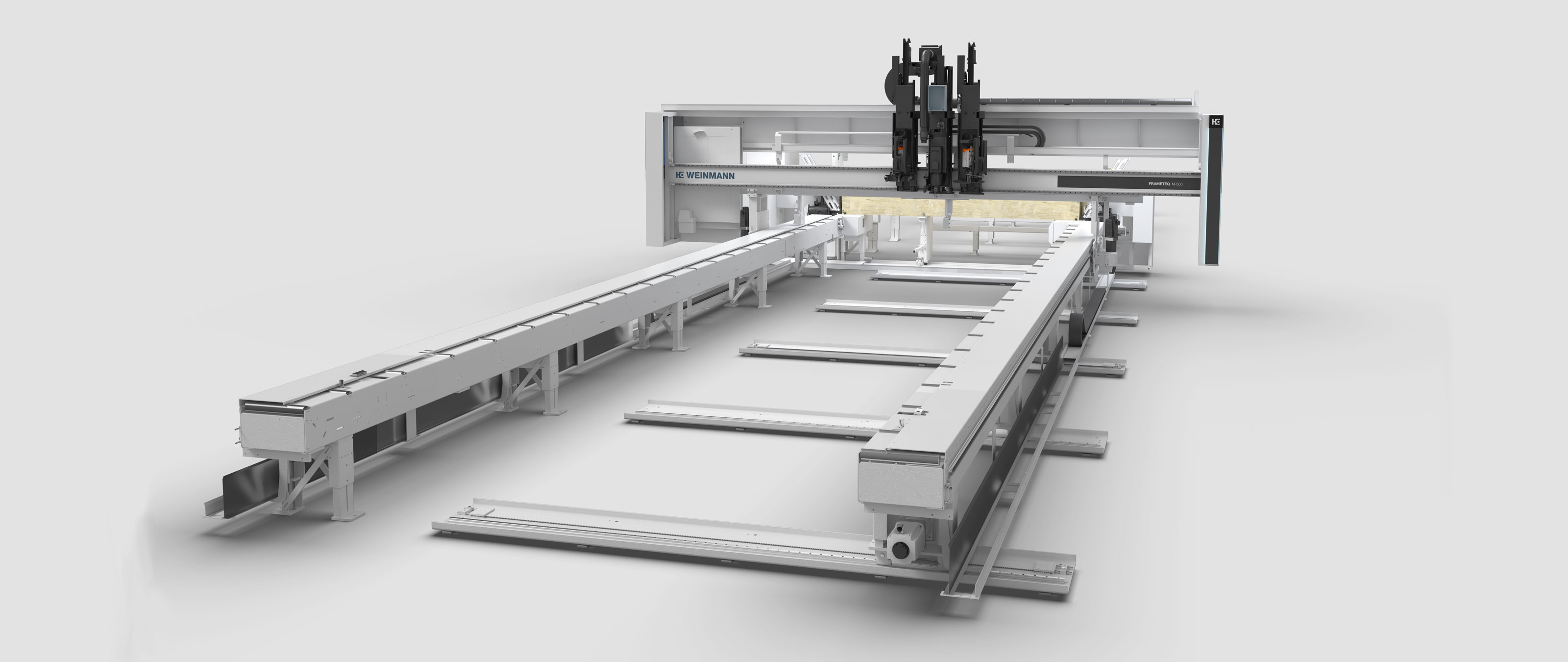

Framing Station & Combi Wall Systems FRAMETEQ M-500

Framing Station & Combi Wall Systems FRAMETEQ M-500

A high-performance combination

The WEINMANN FRAMETEQ M-500 combi wall system can be used to manufacture frame work with sheathing on one side with just one operator – while still ensuring high quality and performance. The frame work is automatically aligned, tensioned and secured. Attachment and processing of the sheathing is also performed as part of an automated process on the same work station.

Benefits

Images

Features

-

Automatic positioning of stud arrangement and fully automatic, perpendicular alignment of the completed frame work

-

Ergonomic working position thanks to optimum processing height and moving control panel

-

Closed elements can be manufactured via expansion with a butterfly turning table

-

CNC axes enable customized nail patterns for frame work components

-

Automatic width adjustment

Technical Data

| Frame work thickness [mm] | 200 Optional: 300 |

| Element thickness [mm] | 250 Optional: 350 |

| Wall height [mm] | 1,200 - 3,200 Optional: 3,800 |

| Max. wall length [m] | 6/ 8/ 10/ 12 |

(Previous product name: Combi Wall System WEK 120)

Brochures