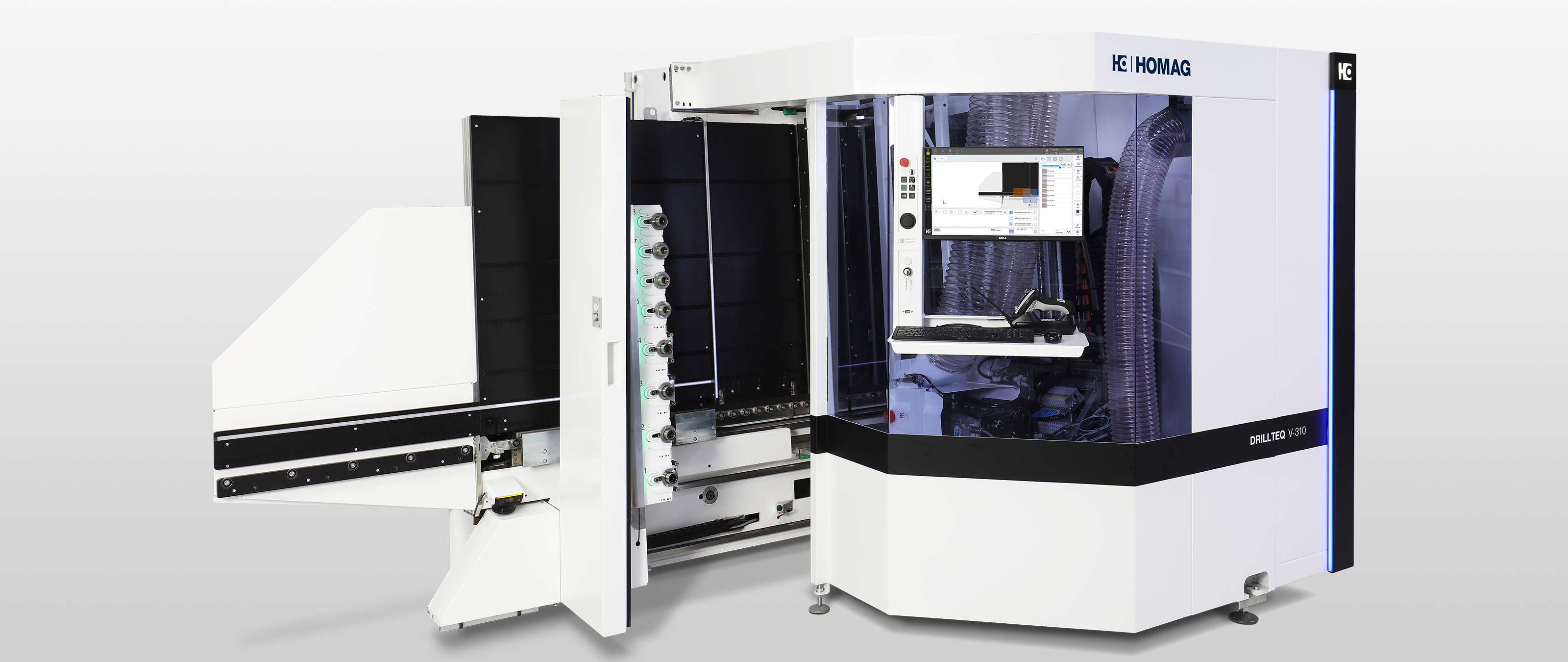

CNC Drilling and Routing Machining Centers DRILLTEQ V-310

CNC Drilling and Routing Machining Centers DRILLTEQ V-310

Maximum cabinet processing. Minimum space requirements. A space-saving miracle that requires just 11 m² of floor space.

The smart concept behind the DRILLTEQ V-310 offers as much functionality as possible in as small a space as possible. It makes optimum use of its 11 m², offering more drilling, more grooving and more trimming than any other machine in this design class. It is even possible to process doors, as well as every type of connector used in furniture construction. Optimize your workpiece handling and tool change handling with intelliGuide LED operator assistance, and look forward to ergonomic processing thanks to the swiveling control unit and the height-adjustable monitor.

Highlights

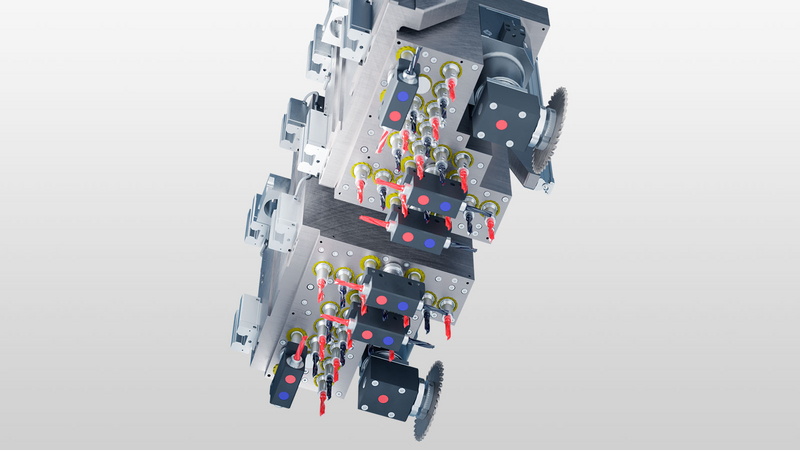

Extensive equipment — up to 45 drilling spindles, 2 groove saws.

Whether classic trimming and drilling or the production of pockets, there are no limits to the choice of furniture connectors.

Energy-efficient processing — the vacuum-free clamping system impresses with its lack of setup times

Images

Features

-

A doweling unit and a C axis with unit interface are available.

-

5° gravity-based tilting for easier workpiece handling

-

Foot switching strip for easy workpiece clamping

-

Plausibility check and workpiece measuring to safeguard processes

-

safeScan — safety concept for optimum and safe interaction between man and machine

-

Barcode scanner to quickly access and read programs and requirements

-

Ergonomic workflows — intuitive operation with fewer manual steps thanks to a small radius of movement due to the machine's compact construction

Technical Data

| Workpiece length [mm] | 200 – 3,050 |

| Workpiece width [mm] | 50 – 1,250 |

| Workpiece thickness [mm] | 8 – 80 |

| Total machine weight [kg] | ca. 3,600 |

| Installation dimensions L x W x H [mm] | 5,300 x 2,260 x 2,160 |

Software

Videos

DRILLTEQ V-310 Vertical CNC Processing Center

The space-saving miracle in CNC processing.

Brochures