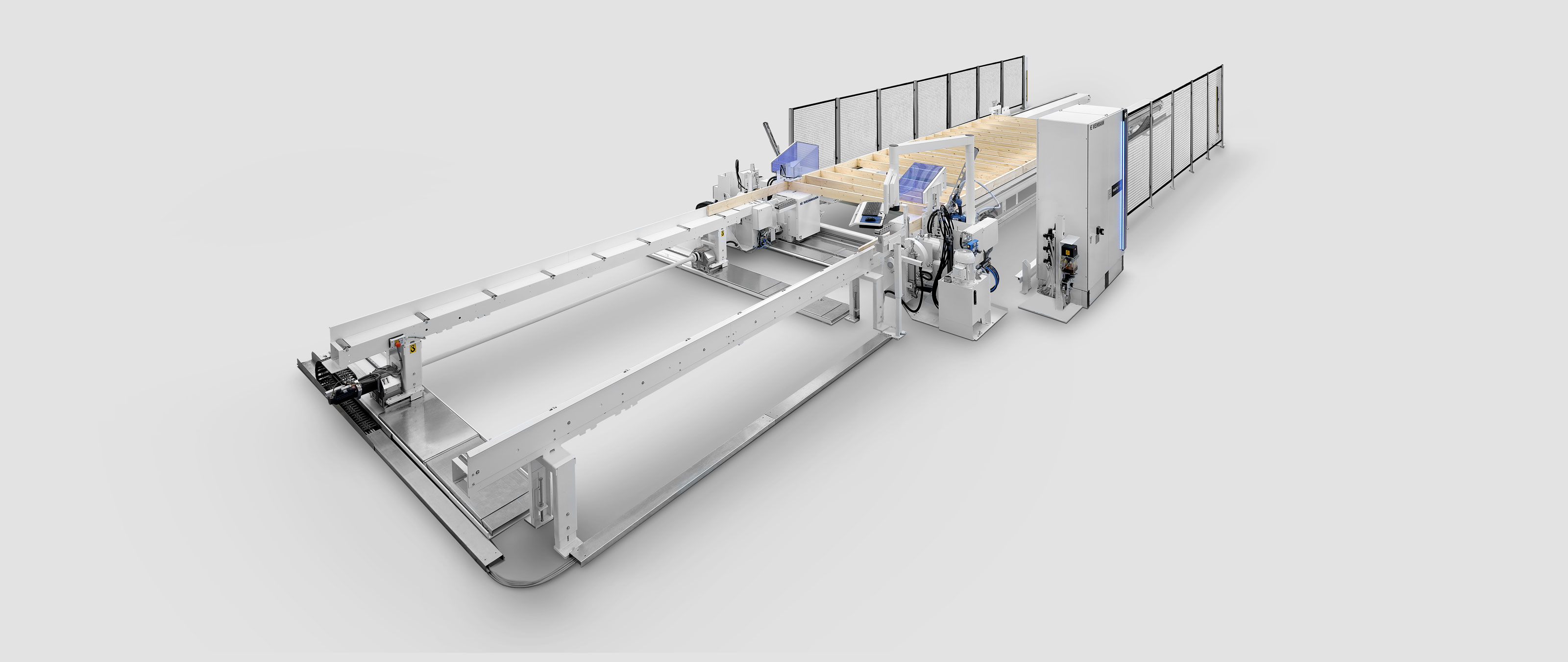

Framing Station & Combi Wall Systems FRAMETEQ F-500

Framing Station & Combi Wall Systems FRAMETEQ F-500

Complex frame works produced with ease

Complex and challenging frame works can be manufactured quickly and easily with the WEINMANN FRAMETEQ F-500 frame work station. Top and bottom plates are fed in manually, positioned at the stops and automatically tensioned. The studs are also automatically positioned, tensioned and secured. The higher level of automation offered in comparison to the FRAMETEQ F-300 significantly increases the performance of the machine.

Benefits

Images

Features

-

Specification of exact stud spacing with NC-controlled outfeed grippers

-

Freely definable nail patterns for different stud types

-

Convenient installation of longitudinal studs using a special device

-

Very easy to use: clear screen display and swiveling control panel

-

Fully automatic transfer of data from all popular CAD programs for timber work

Technical Data

| Wall thickness [mm] | 75 - 200 Optional: 300 |

| Wall height [m] | 1,5 - 3,2 Optional: 3,8 |

| Wall length [m] | 6/ 8/ 10/ 12 |

| Production capacity [mm / min] | 800 - 1,500 |

(Previous product name: Frame Work Station WEM 150)

Videos

Prefab house, Frame work station, Carpentry, beam processing

Video: Robot technology in timber framing

Brochures