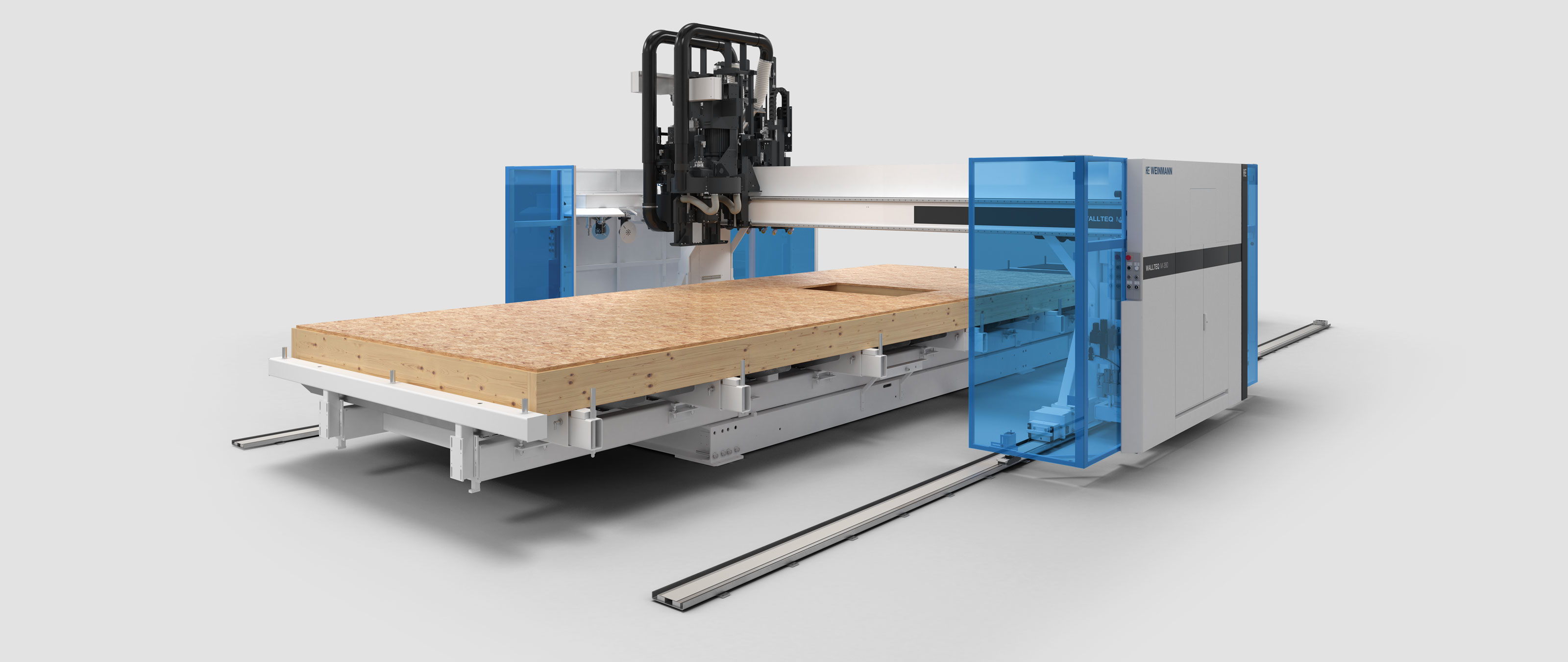

Multifunction Bridge WALLTEQ Nesting

Multifunction Bridge WALLTEQ Nesting

Use just one machine for complete panel processing - mounting, sawing, trimming, drilling and nesting

The nesting function lets you optimize your offcuts while minimizing any material waste that is generated. There is a protection board on the processing table. The operator places the panel they wish to process on the protection board. The data is sent to the machine using the nesting software. The WALLTEQ multifunction bridge then cuts the panel in a fully automated process based on the data specification. This removes the need to leave the small holding tabs that hold it in position, or manually rework the finished component.

Benefits

Images

Features

-

fastenerSwitch

The first quick change system for fastening units -

The WALLTEQ M-340 and WALLTEQ M-380 multifunction bridges can be used for nesting and timber frame construction

-

No setup time for the multifunction bridge when used for nesting and timber frame construction, as no clamping or positioning is required

-

The fully automatic tool changer provides space for up to 12 tools, which can be selected according to individual requirements

-

Use just one machine for mounting (stapling, nailing, screwing), processing (sawing, trimming, drilling) and nesting

-

Rapid and consistent data transfer; nesting software automatically processes the BTLx/WuP files generated by CAD/CAM programs and converts them into MPR files

Technical Data

| Max processing heigh [mm] | 500 |

| Max processing width [mm] | 3.200 |

| Processing length | customer specific up to 50 m, or greater lengths possible |

Technical information without guarantee!

(Previous product name: WMS multifunction bridge for nesting)

Brochures