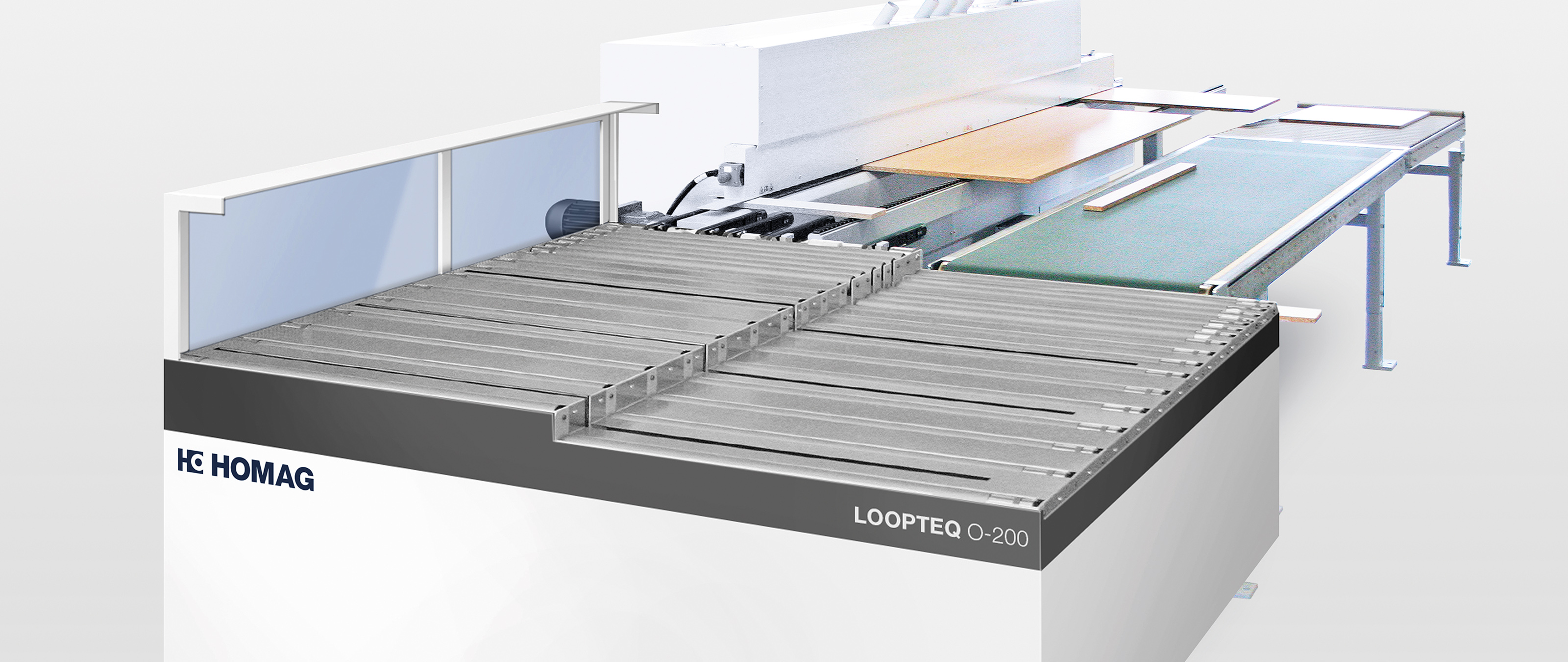

Return Conveyors LOOPTEQ O-200

Return Conveyors LOOPTEQ O-200

The entry to a comfortable material flow

The LOOPTEQ O-200 is the perfect supplement for unilateral edge banding machines as essential support for an economic workpiece return. The production process will be more efficient, whether batch size 1, batch, or serial production. The LOOPTEQ O-200 is excellently suited for customers with small, narrow, and medium-sized workpieces.

Benefits

Images

Features

-

The LOOPTEQ O-200 perfectly harmonizes in size, capacity, and speed with HOMAG Group‘s unilateral edge banding machines

-

Sensor controlled turning bolt (optional) for a better handling of short and narrow parts, e.g. for fronts of drawers

-

Small roller gib (optional) to support wide workpieces

-

Simple belt cleaning equipment is already included in the standard

Technical Data

| Workpiece length | 300 - 2,500 mm |

| Workpiece width | 50 - 1,450 mm |

| 4-sided processing* min. workpiece length | 300 x 300 mm |

| 4-sided processing* max. workpiece length | 1,450 x 1,450 mm |

| Workpiece thickness | 8 - 60 mm |

| Workpiece weight max. | 50 kg |

| Mass per unit area | 25 kg/m² |

| Working height | 835 - 950 mm |

| Feed speed | 8 - 25 m/min |

*Larger workpieces can be returned or even fed out at 4-sided processing with manual support during crosswise offset and turning.

(Previous product name: Return conveyor BOOMERANG® TFU 120)

Here's how your colleagues produce

Brochures