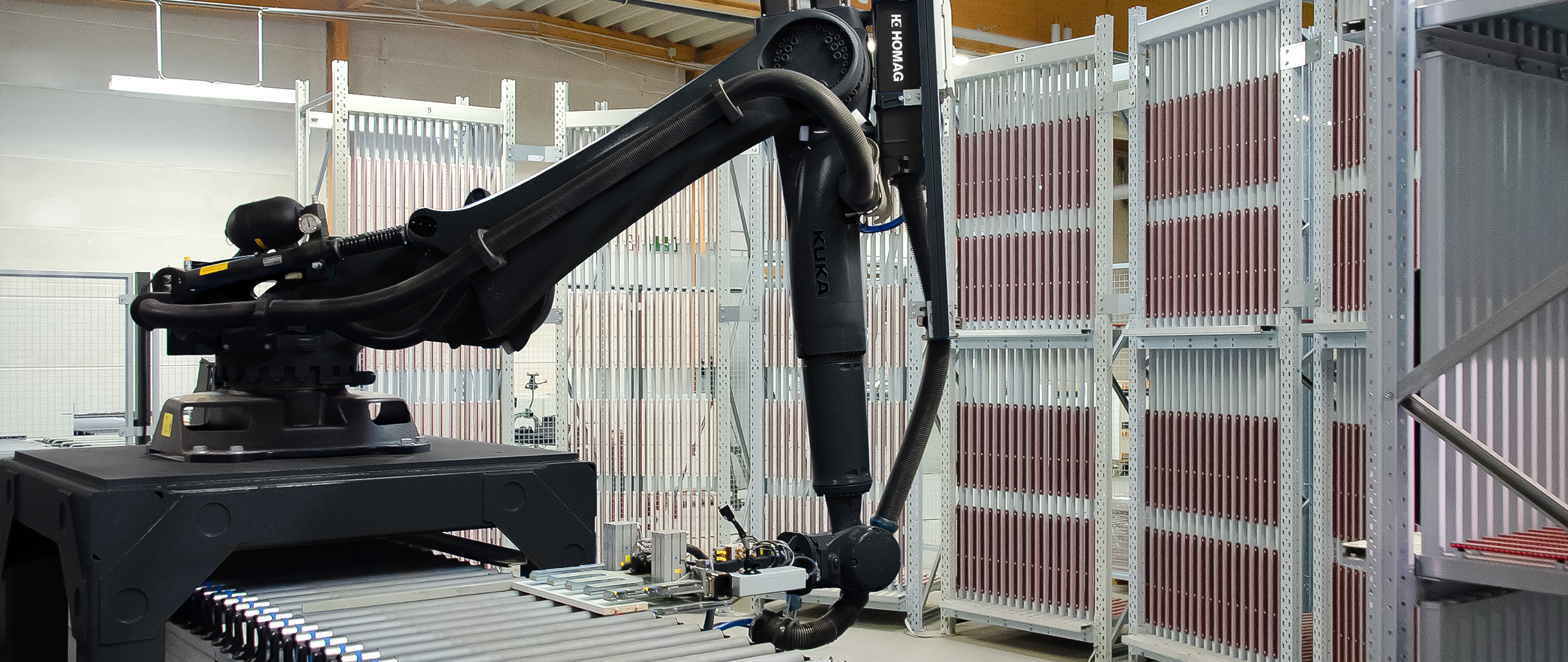

Robot Solutions for the Furniture Industry SORTBOT R-300

Robot Solutions for the Furniture Industry SORTBOT R-300

More Output without Waiting Times

Robots ensure product quality and improve workplace conditions. As reliable solution for buffering, decoupling, and sorting, robots enhance production performance and increase yield. High repeat accuracy and availability makes a robot the central element of a sorting cell and enables production processes able to schedule.

Benefits

Images

Features

-

Up to 16 shelves in a circle arrangement possible, shelves are equipped with up to 3 levels

-

Various shelf combinations to pick up narrow parts up to a width of 240 mm (optionally)

-

Direct access to each workpiece enables high system speed

-

Flexible component arrangement offers variable storing capacity

Technical Data

| Shelf* | Levels | Sheds | Workpiece length [mm] | Workpiece width [mm] | Workpiece thickness [mm] |

|---|---|---|---|---|---|

| Typ A | 1 | 1 x 16 | 240 - 2,800 | 240 - 1,000 | 16 - 19 |

| Typ B | 2 | 2 x 16 | 240 - 1,400 | 240 - 1,000 | 16 - 19 |

| Typ C | 3 | 3 x 16 | 240 - 800 | 240 - 1,000 | 16 - 19 |

| Typ D | 2 | 2 x 16 | 240 - 900 240 - 2,800 | 240 - 1,000 | 16 - 19 |

| Typ E | 1 | 1 x 14 | 240 - 2,800 | 240 - 1,000 | 19 - 25 |

| Typ F | 2 | 2 x 14 | 240 - 1,400 | 240 - 1,000 | 19 - 25 |

| Typ G | 3 | 3 x 14 | 240 - 800 | 240 - 1,000 | 19 - 25 |

| Typ H | 2 | 2 x 14 | 240 - 900 240 - 2,800 | 240 - 1,000 | 19 - 25 |

*Up to 16 shelves in a circle arrangement possible. Shelves are equipped with up to 3 levels.

Videos

Robot Sorting Cell

The robot sorting cell is interesting for everyone who produces furniture in batch size 1.

Brochures